G-Link Deep Earthing System

g-Link GROUNDING SYSTEM

Benifits

- Copper earthing wire can be driven down deep in to the ground and firmly anchoved to stay there. Creates lite long link with earth.

- The earth electrode and ground conductor is same which avoids every joints and connectors.

- Copper conductor is used, the extension tube acts as an anode and provides good corrosion protection

- The system has low overall weight compared to other systems

- The total cost for a finished grounding will be lower than for a conventional grounding

Coper earthing wire can be driven down deep in to the ground creates and firmly anchored to stay their. Life long link with earth. The earth electrode and ground conductor is same which avoids every joining and connectors.

THE FUNCTION IS SIMPLE:

- Ground conductor is inserted into the hardened tip and pinched by the Leading Rod.

- The extension Rod has a guide pin which during insertion is inserted into the Leading Rod.

- The transition resistance can be measured continuously. When the appropriate value is reached, the drive is interrupted and the last extension tube pulled up (and can be used again).

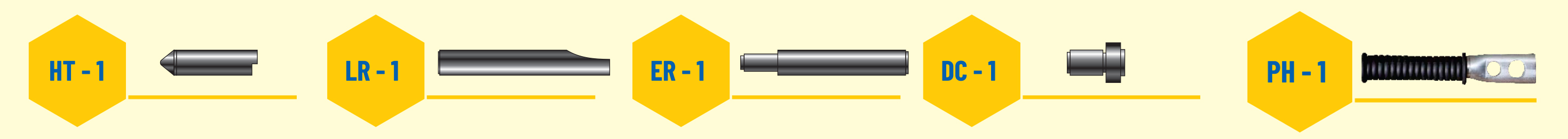

THE SYSTEM'S STRUCTURE AND FUNCTION CONSISTS OF THE FOLLOWING 5 PARTS:

CHARACTERISTICS:

- Hardened Tip

- Driving Cap

- Leading Rod

- Extension Rod.

- Pull Back Handle.

Practical Advice

- Plan the grounding. What are the conditions in the ground? Is it possible for parallel earthing?

- Determine the resistivity of the soil. Based on it and maximum lead resistance it is possible to assess how much lead is needed.

- Start the drive by locking the conductor in the hardened tip with the Leading Rod. For loose soil, there is sufficient sledge and impact bolt. In heavier soil / greater depth, compressor hammer should be used. NB Do not rotate the blown neck during work.

- Make sure that the conductor goes with the pipe into the ground. If it does not, there are the following possibilities:

- The pipe continues and the conductor stops; the leader has loosened and can be pulled up or the spear bent. Both stop: it is hit on rock or rock. If the stone does not crack after about 10 seconds, change position restart.

- In case of interrupted driving - start at least 1.5 times away from the lead length already driven down.

- Preferably measure the transition resistance continuously during grounding operation

THEORY:

- Grounding system without joints. The electrode consists of a conductor driven by a system consisting of long steel pipes.

- A hardened steel tip paves the way for the conductor which is inserted into the steel tip and clamped by the front pipe. For each 0.8 m length of folded line and pipe, an extension pipe was pushed into the previous pipe.

- Since the transition resistance can be continuously measured at the other end of the conductor, the drive is interrupted when the appropriate value is obtained and the last extension tube is then pulled up.

- The drive is normally carried out with the help of an impact Cap DC-1.

BENEFITS:

g-Link grounding system has many advantages:

- The earth conductor has no joints - no danger of contact failure.

- Skewers and front pipes are manufactured for conductors of varied cross sections: 25-70 mm². Can be used for different types of conductors, such as soft or hard copper, galvanized or stainless steel.

- When a copper conductor is used, the extension tube acts as an anode and provides good corrosion protection.

- Full control of the conductor and spear being followed and the possibility of continuous measurement of the transition resistance.

- Due to the fact that the system consists of a few parts, the drive is both uncomplicated and reliable.

- The system has low overall weight compared to other systems.

- The total cost for a finished grounding will be lower than for conventional grounding